Forged aluminum alloy buckle

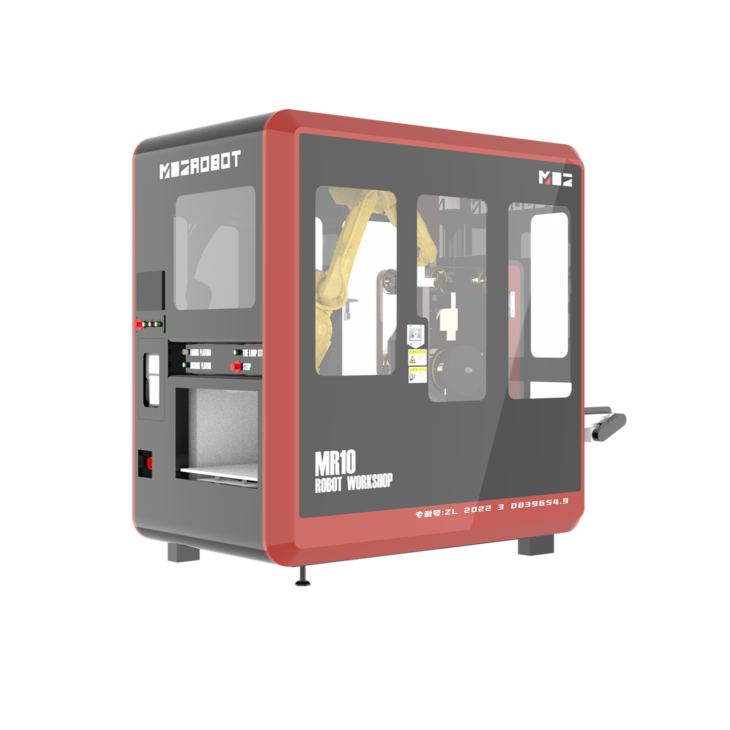

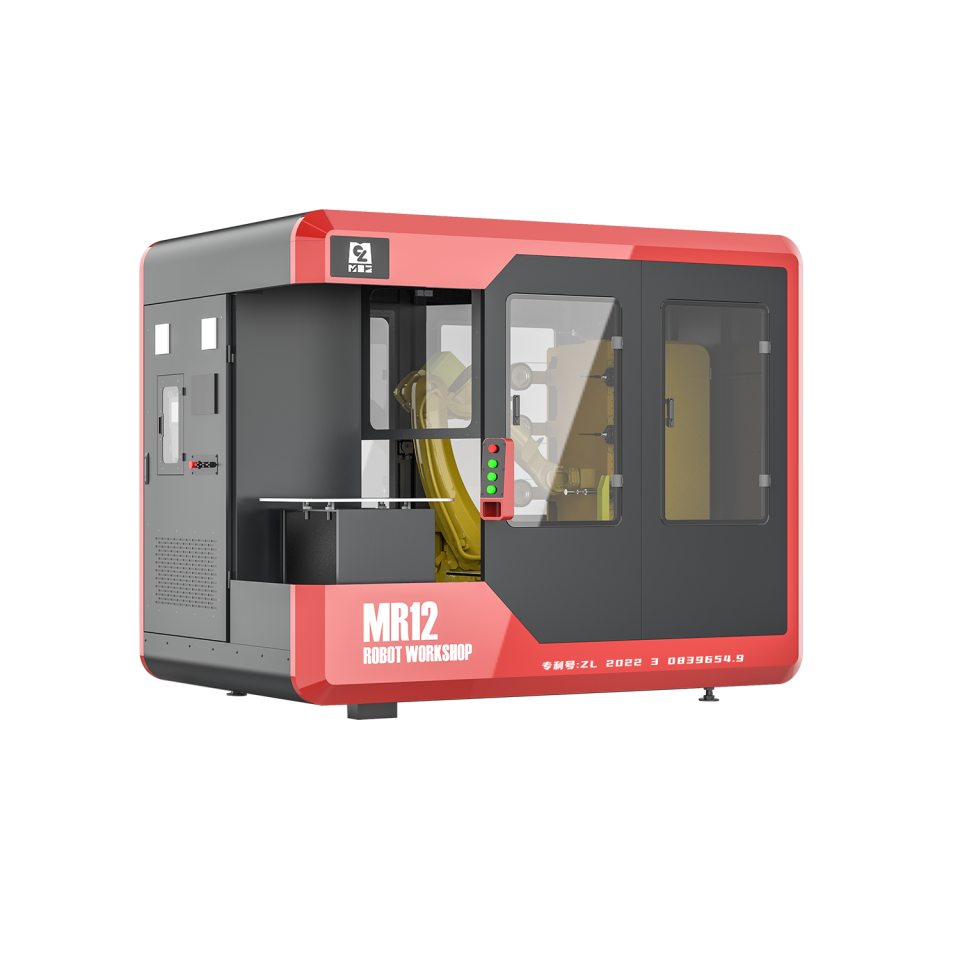

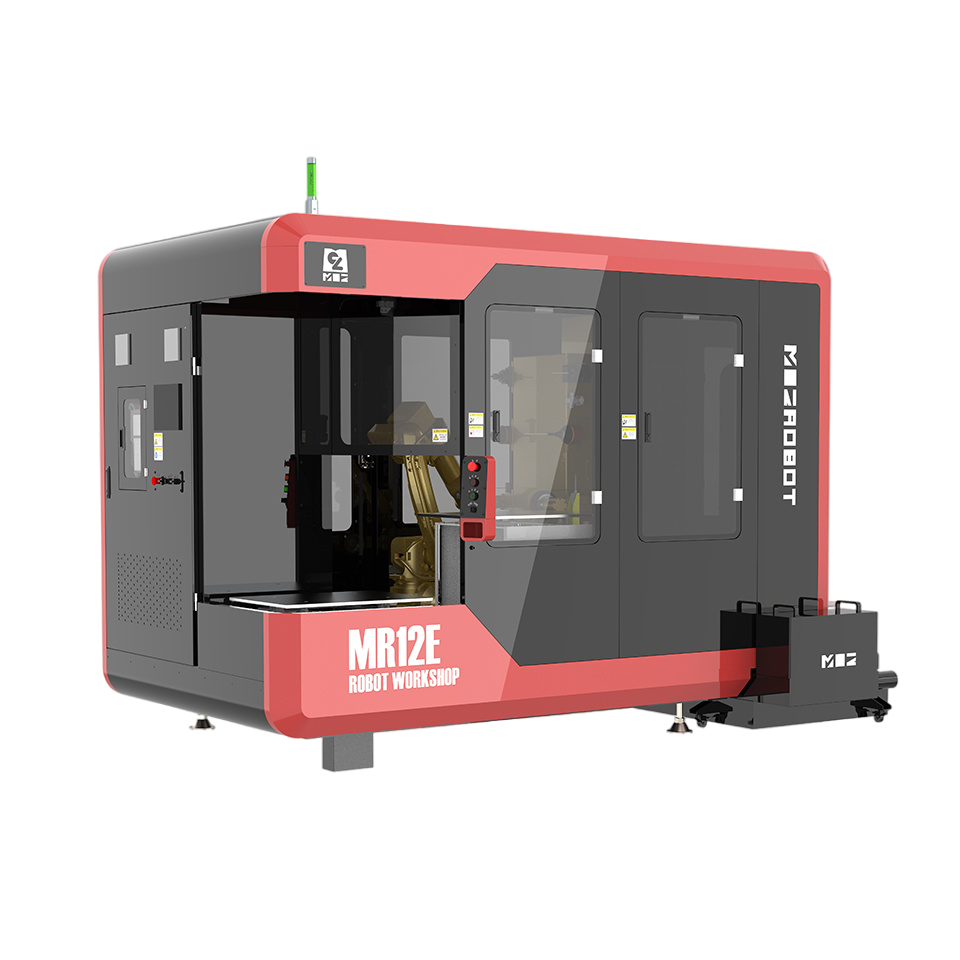

Recommended equipment model: MR12

Deburring time: 146s±5s

Loading and unloading time: 8s

| Process |

Process Description |

Processing Location |

Tool |

Tool Consumables |

| 1 |

Polishing |

Feed Port |

Belt Sander |

80-grit Sand Belt |

| 2 |

Remove Feed Port |

Feed Port |

Main Spindle |

Milling Cutter |

| 3 |

Deburring |

Parting Line |

Radial Floating File Machine |

Coarse Tooth File |

| Summary |

Comprehensive assessment: This product can be polished and deburred by a robot for mass production. |

|||

Gripping Illustration

| 1 |

|

2 |

Fixture plate dimensions: 550*750mm The upper and lower material platforms can hold approximately 40 products. |

| Description | The product has a large feed port, making it difficult to quickly remove during polishing. The polishing process includes time for removing the gate, which wastes time and results in a longer overall cycle time. |

||

|

|