What are the applications of polishing and deburring robots in the automotive parts industry?

Release time:

2025/02/19

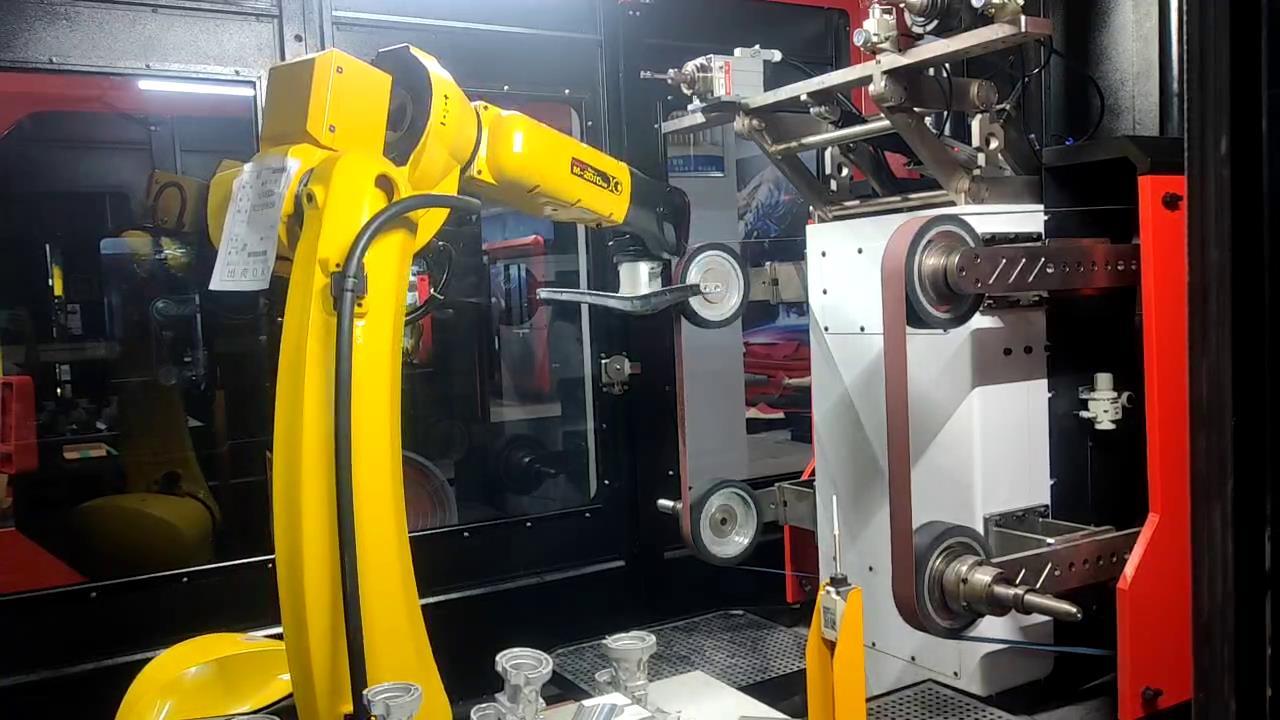

With the rapid development of the automotive manufacturing industry, the precision and surface quality of parts are increasingly valued. Especially in the production of aluminum die castings, how to efficiently and accurately remove burrs has become a major challenge for many manufacturers. In recent years, the application of automotive parts polishing and deburring robots has brought revolutionary changes to aluminum die casting manufacturers.

I. Challenges of Burr Problems in Aluminum Die Castings

Aluminum die castings, due to their lightweight and high-strength characteristics, are widely used in automotive manufacturing. However, during the die-casting process, due to the influence of factors such as molds and materials, burrs often appear on the surface of the castings. These burrs not only affect the appearance quality of the product but may also affect the assembly accuracy and performance.

II. Advantages of Automotive Parts Polishing and Deburring Robots

For aluminum die-casting burr problems, traditional polishing methods have shortcomings such as low efficiency and unstable quality. Automotive parts polishing and deburring robots, with their advantages of high precision, high efficiency, and high stability, have become the ideal choice for solving this problem.

High Precision: The robot uses an advanced vision system and a precise control system to accurately identify and locate burrs on die castings, achieving precise polishing.

High Efficiency: The robot has the ability to respond quickly and operate continuously, able to complete the polishing of a large number of die castings in a short time, improving production efficiency.

High Stability: The robot's operation is stable and reliable, avoiding errors caused by human factors and ensuring the stability of product quality.

III. Application of Automotive Parts Polishing and Deburring Robots in Aluminum Die Casting Manufacturers

With the continuous maturity of technology and the popularization of applications, more and more aluminum die-casting manufacturers are beginning to introduce automotive parts polishing and deburring robots. These robots can not only solve burr problems but also improve the overall quality and production efficiency of products, reducing production costs.

Improved Product Quality: Through precise polishing, the robot can remove burrs from the surface of die castings, making the product surface smoother and flatter, improving the appearance quality and assembly accuracy.

Improved Production Efficiency: The robot has the ability to work efficiently and continuously, completing the polishing of a large number of die castings in a short time, shortening the production cycle, and improving production efficiency.

Reduced Production Costs: By introducing robot automation, aluminum die-casting manufacturers can reduce labor costs, reduce error rates and scrap rates in the production process, thereby reducing production costs.

IV. Future Outlook

With the continuous development of the automotive manufacturing industry, the requirements for the precision and surface quality of parts will become increasingly higher. Automotive parts polishing and deburring robots, as efficient and precise automated production tools, will play an increasingly important role in the future of automotive manufacturing. At the same time, with continuous technological advancements and widespread adoption, robots will gradually achieve a wider range of applications and higher levels of intelligence, bringing more opportunities and challenges to aluminum die-casting manufacturers.

Latest News