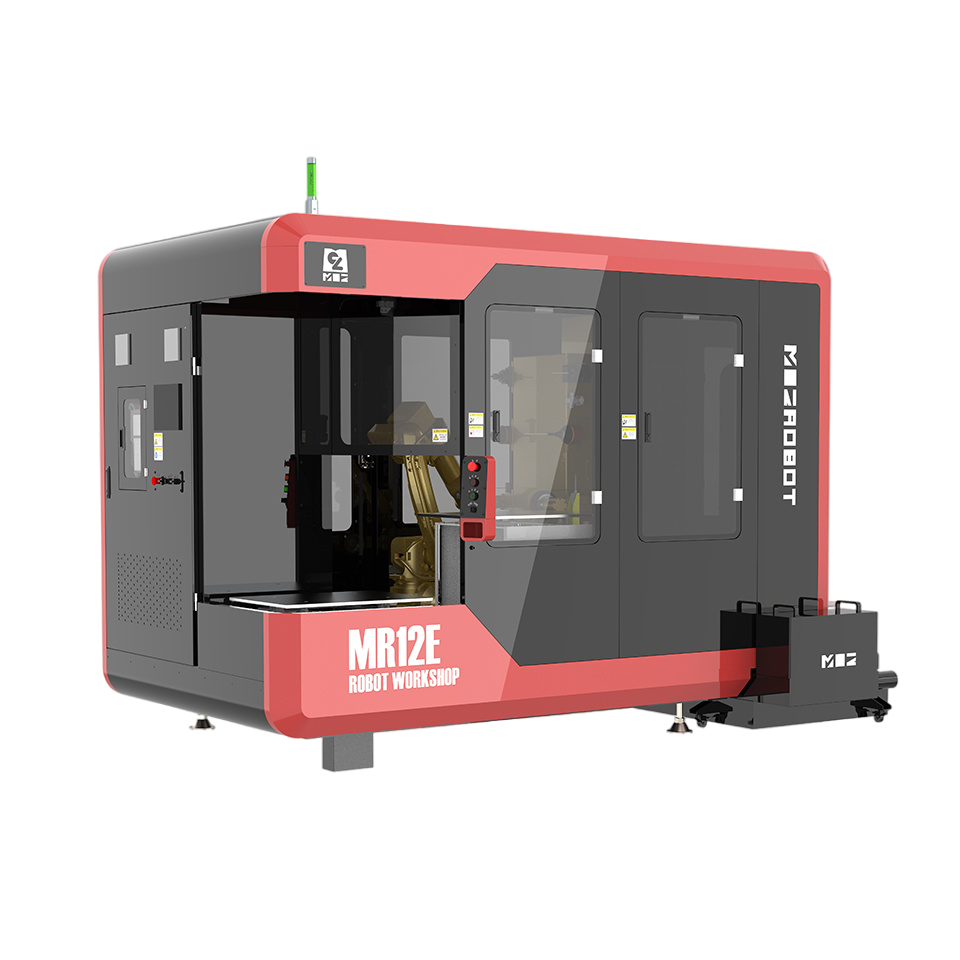

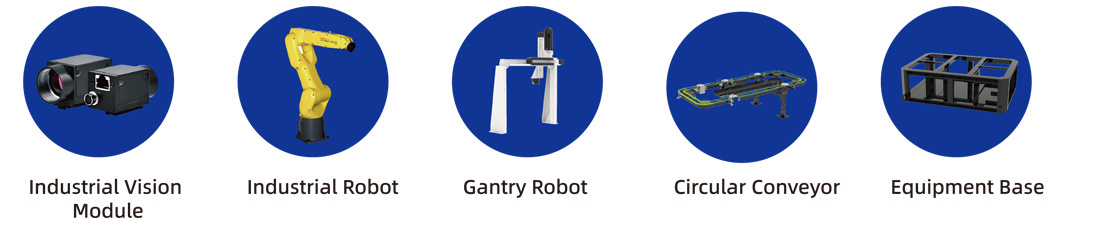

MS-250C Intelligent 3D Visual inspection Workstation

The Ms-250cSmart 3D Vision InspectionWorkstation uses high-precision sensors and smart algorithms for accuratesurface recognition and positioning, boosting grinding precision and efficiency. it handles complex surfaces and finedefects effortlessly, supporting high-guality production and advancing automation in smart manufacturing.

|

Cloud-Based AlgorithmModel Repository |  |

Extensive Defect Sample Library |

|

Unsupervised LearningAlgorithms/small sampleTraining |  |

Self-FeedbackDeep Learning |

Key Metrics for Vision Inspection Equipment

| Robot end-of-arm tooling line speed reaches | 1000 mm/s |

| Image acquisition time (CT value) at each point | 0.3S |

| Zero-tolerance defect miss detection rate | 0% |

| Overall miss detection rate | <1% |

| False detection rate | <5% |

| Detection material | Plastic parts / Metal parts / Special materials, etc. |

Keywords: MS-250C Intelligent 3D Visual inspection Workstation